sampling

Flow Proportional Automatic Continuous Sampler

The vessel may want to carry out its own on board tests, or send the sample to an independent organisation like FOBAS for testing. In this case, the supplier may give the ship an additional sample. If not, or if the sampling of the fuel cannot be witnessed, then it may be necessary for the ship to take its own samples. The most practical and economical method of doing this is to employ a continuous drip sampler.

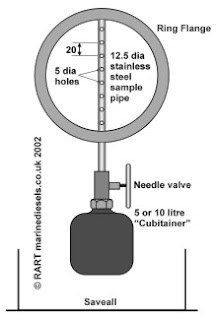

| The sampler consists of a ring flange with a 12.5mm dia sample pipe spanning the diameter of the flange. 5mm dia sample holes facing the direction of flow are drilled at 20mm intervals. At the end of the sample pipe is a needle valve for controlling flow and a connection for attaching a semi transparent flexible collecting container. The normal place to position the sampler is between two flanges at the bunker station adjacent to the isolating valve.

|

| Once bunkering commences flush the sample pipe through and then connect the collecting container. Adjust the needle valve to give a steady drip. At the end of bunkering, the container is removed and the contents transferred to sample bottles. If a sample is to be given to the supplier, then ask his representative to witness the disconnection of the container and the filling and sealing of the sample bottles. If declined, then note this on the bunker receipt. Label the bottles as required. Normally four samples are required: · Sample for supplier · Sample for on board testing · Sample for independent analysis · Sample for retention on board. |

|

Often a sample is required for compatability testing before bunkers are commenced. In this case, a sample drawn from the delivery tanks is used, but it should be borne in mind that this is not a representative sample.

I like this article. I was searching over search engines and found your blog and its really helps thank you so much.Fuel Oil Delivery Companies Pennsylvania

ReplyDelete